INDUSTRIAL CONVEYOR BELTS

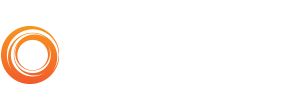

Steel construction belts from National Element are especially adaptable to conveying heavy, rough or sharp material. An assembled belt consists of hinged links, side wings, tubes, thru pins and dual strands of roller chain. The hinged links are assembled in horizontal rows by passing the tube through the hinges. The thru pins are inserted into the tube and fastened into the side chains thus supporting the links and causing the chain to take all the tension.

OVERVIEW

- Plain pulley, snubbed pulley, pressure roll, tandem and tractor drives

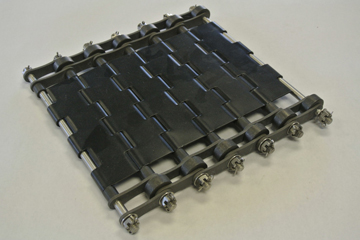

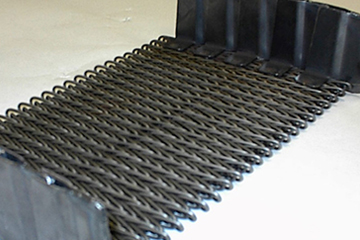

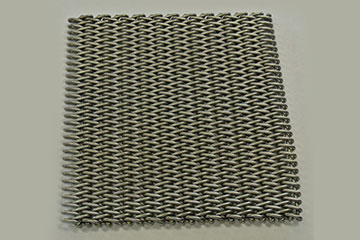

- U-Link, Hinge plate and Wire mesh

- Piano hinge available in light, medium, medium-heavy and heavy depending on allowable belt pull

- Operate in fluids, oils or solvents

- Side wings mig welded to the outer links

- Full variety of pins available light duty, medium, medium-heavy and heavy-duty belts

ENGINEERING SPECS

Bushings

Steel bushings = 15-18% coefficient of friction

Nylatron bearings = 10-13% coefficient of friction

Roller bearings= 4-5% coefficient of friction

Steel Links

Standard plain steel links precision welded in widths of :

24″ ( 1/8” thick flat top and piano hinge plate belts)

6″ (3/16” belt)

12” (¼ belt)

Hinges

Hinges formed in 1-1/2″ – 3″ increments on the link to allow special belt widths of the same 1-1/2″ increment.

Side wings

Side wings interlocked and afford continuous overlapping through bends and over the sprockets. Mig welding to the belt prevents thin pieces of material from getting under the wing.

Standard sizes:

1/8″ thick x 1-1/2″ for 2-1/2″ pitch

1/8″ thick x 2-1/2″ for 4″ pitch

3/16″ thick x 3″ or 4″ for 6″ pitch

3/16″ thick x 4″ or 6″ for 9″ pitch

Tubes

The tubes are .760″ I.D. x .970″ O.D. steel running through the hinges for the complete belt width and rotates on the thru pin for a better bearing area. Maintenance is easy because it is not necessary to disconnect the belt at a hinge point to remove a pin. It is the tube that holds the belt together.

Pins

1/2″ dia. thru pin with milled ends and 5/32″ “S” pin

3/4″ dia. pin with milled ends and 1/4″ cotter pin

heavy-duty belt pin with milled and threaded ends and 3/4″ lock nut

3/4″ dia. split pins for easy maintenance in tight spaces

Pin, tube and hinge provides a 1-1/2″ thick heavy-duty joint

APPLICATIONS

- Baled scrap

- Forgings

- Loose metal scrap

- Metal chips

- Parts

- Stampings

- Waste Paper

- Municipal Waste

Conveyor Belts

Call us Now

NEI Specialists know the in's and out's of tolerance, capability and utility. Go ahead and test us on your toughest requirements. We thrive on making, altering and customizing anything to make it work harder, faster or last longer.

(248) 486-1810